Xalalka qalabka caafimaadka

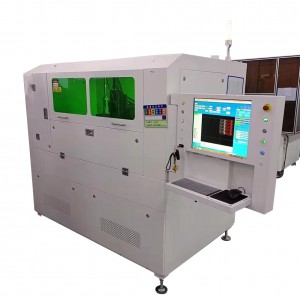

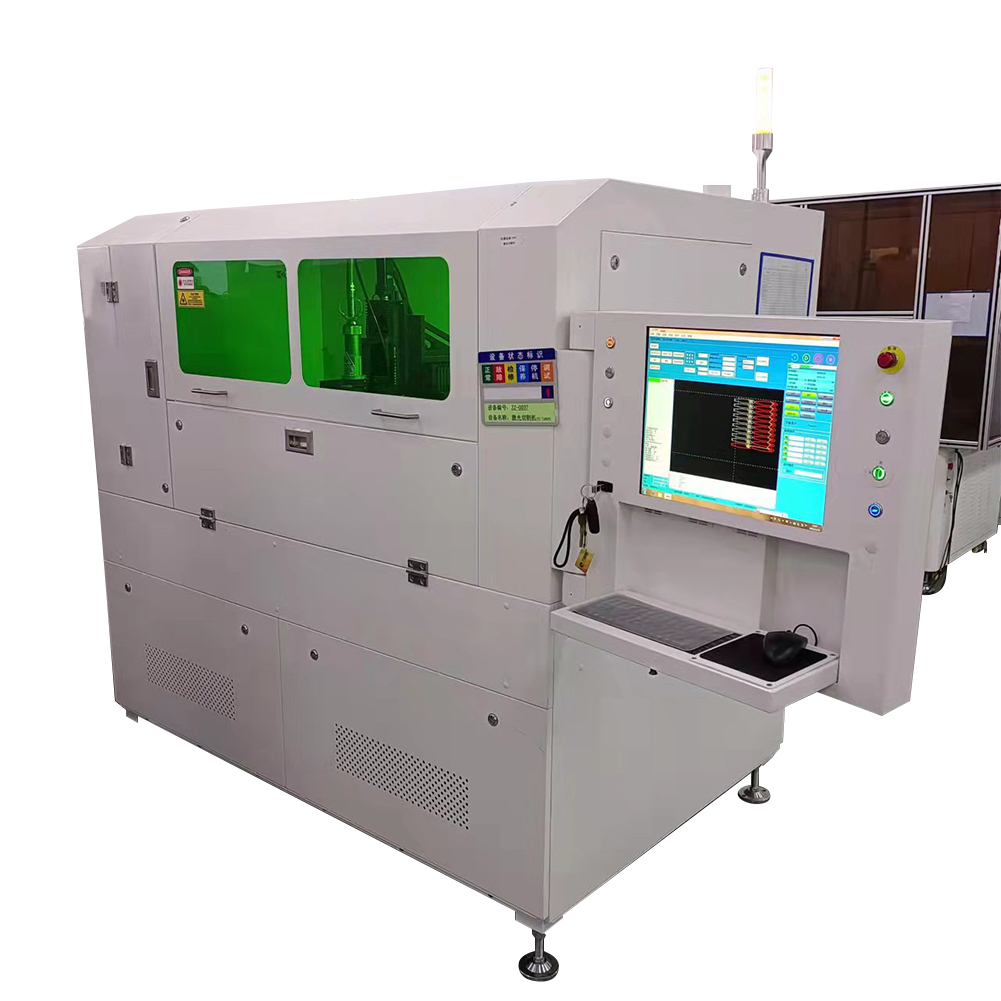

Mashiinka goynta laser shan geesoodka ah ee qalabka qalliinka TLM600

Qalabka Qalliinka Mashiinka Goynta Laser

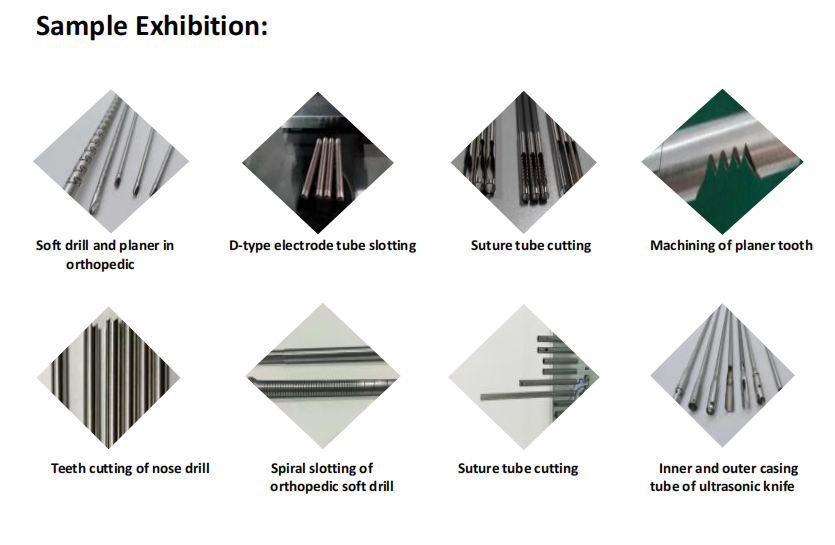

Mashiinka goynta laser shan dhidibQalabka qalliinka waxaa loo tixraaci karaa mashiinka goynta laysarka ee qalabka qalliinka.Waxaa inta badan loo isticmaalaa habaynta centripetal, toosan, iyo sifooyinka furitaanka isku dhafan ee tuubooyinka isodiametric, tuubooyinka dhexroorka doorsooma, iyo qalabyada qorshaysan.Qalabka la mashiin karo waxaa ka mid ah 304 iyo 316L oo ah bir aan lahayn., Nikkel-titanium alloy, cobalt-chromium aluminium, aluminium, cobalt, lithium, magnesium birta, iwm sida planer jilicsan lafaha, lafaha jilicsan jilicsan helical slotting, godka D-nooca electrode tuubada, tuubada stapler samaynta, gacmo muraayad adag, sanka daloolida furitaanka iliga, tube stapler samaynta, ultrasonic mindida gudaha iyo gacmaha dibadda, iwm Qalabku wuxuu qaataa nidaamka taageerada gacanta tuubada dhuuban ee saxda ah ee isku dhafan kaas oo la qabsanaya qaabka isbeddelka dulqaadka, wuxuuna leeyahay faa'iidooyinka naqshadeynta sare iyo saxnaanta mashiinka sare.

FarsamoParameters:

| Xawaaraha hawlgelinta ugu badan | 500mm/s (X1);500mm/s (Y1/Y2);50mm/s (Z); | |||

| Meelaynta Saxnaanta | ± 3um (X1) ± 3um (Y1/Y2) ± 5um (Z) | |||

| Xaqiijinta Meelaynta Soo noqnoqota | ± 1um (X1) ± 1um (Y1/Y2) ± 3um (Z) | |||

| Qalabka mashiinka | 304&316L&Ni-Ti&L605&Al&Gu&Li&Mg&Fe iwm. | |||

| Baaxadda farsamaynta diyaaradda | 450mm*600mm; | |||

| Nooca laser | Fiber laser; | |||

| Dhererka hirarka leysarka | 1030-1070±10nm; | |||

| awoodda laysarka | 200W&250W&300W&500W&1000W&QCW150W ikhtiyaarka ah; | |||

| Qalabka korontada | 220V± 10%, 50Hz;AC 25A (goobiyaha ugu weyn); | |||

| Qaabka faylka | DXF&DWG&STP&IGS; | |||

| Cabirka qalabka | 1280mmx1320mmx1600mm; | |||

| Miisaanka qalabka | 1500kg; | |||

TLM600

La qabsi xoog leh

① Iyadoo laser goynta qalalan & goynta qoyan & qodista & daloolista iyo awoodaha mashiinnada kale ee wanaagsan

②Centripetal & mid toosan & qaabka furitaanka isku dhafka ah ee lagu taageerayo tuubada dhexroorka siman

③Waxa uu farsamayn karaa 304&316l&Ni-Ti&L605&Al&Gu&Li&Mg&Fe iyo agabka kale

④ Waafaqin sax ah nooca D-chuck & ER taxane chuck & saddex daan oo daanka ah iyo nidaamka kale ee saxda ah ee tuubada dhuujinta

⑤ Qaado nidaamka taageerada gacan-gacmeedka tuubada dhuuban ee saxda ah ee isku dhafka ah oo leh kala duwanaansho u dulqaadasho qaab is-qabad ah

⑥ Bixi nidaamka u dhigma ee tuubo dhuuban oo sax ah habayn toos ah oo quudin iyo raritaan toos ah

⑦Ku qalabaysan 2D & 2.5D & 3D CAM nidaamka software-ka iskood u horumaray ee micromachining laser

Baaxadda codsiga:

Micromachining Laser ee qalabka qalliinka iyo lafaha sida endoscope adag & ultrasonic scalpel & endoscope& stapler & qalabka tolida & layliga jilicsan & planer & irbad dalool & sanka dalool

Mashiinka saxnaanta sare:

① Ballaca tolitaanka yar ee goynta: 18 ~ 30um

② Saxnaanta mashiinka sare: ≤ ± 10um

③Tayada wanaagsan ee jeexida: ma laha burr & jeexitaan siman

④ Waxtarka mashiinka sare: goynta hal-mar ah iyada oo loo marayo gidaarka hal dhinac ah & mashiin quudin joogto ah oo toos ah

FarsamoParameters:

| Xawaaraha hawlgelinta ugu badan | 500mm/s (X1);500mm/s (Y1/Y2);50mm/s (Z); | |||

| Meelaynta Saxnaanta | ± 3um (X1) ± 3um (Y1/Y2) ± 5um (Z) | |||

| Xaqiijinta Meelaynta Soo noqnoqota | ± 1um (X1) ± 1um (Y1/Y2) ± 3um (Z) | |||

| Qalabka mashiinka | 304&316L&Ni-Ti&L605&Al&Gu&Li&Mg&Fe iwm. | |||

| Baaxadda farsamaynta diyaaradda | 450mm*600mm; | |||

| Nooca laser | Fiber laser; | |||

| Dhererka hirarka leysarka | 1030-1070±10nm; | |||

| awoodda laysarka | 200W&250W&300W&500W&1000W&QCW150W ikhtiyaarka ah; | |||

| Qalabka korontada | 220V± 10%, 50Hz;AC 25A (goobiyaha ugu weyn); | |||

| Qaabka faylka | DXF&DWG&STP&IGS; | |||

| Cabirka qalabka | 1280mmx1320mmx1600mm; | |||

| Miisaanka qalabka | 1500kg; | |||

TLM600

La qabsi xoog leh

① Iyadoo laser goynta qalalan & goynta qoyan & qodista & daloolista iyo awoodaha mashiinnada kale ee wanaagsan

②Centripetal & mid toosan & qaabka furitaanka isku dhafka ah ee lagu taageerayo tuubada dhexroorka siman

③Waxa uu farsamayn karaa 304&316l&Ni-Ti&L605&Al&Gu&Li&Mg&Fe iyo agabka kale

④ Waafaqin sax ah nooca D-chuck & ER taxane chuck & saddex daan oo daanka ah iyo nidaamka kale ee saxda ah ee tuubada dhuujinta

⑤ Qaado nidaamka taageerada gacan-gacmeedka tuubada dhuuban ee saxda ah ee isku dhafka ah oo leh kala duwanaansho u dulqaadasho qaab is-qabad ah

⑥ Bixi nidaamka u dhigma ee tuubo dhuuban oo sax ah habayn toos ah oo quudin iyo raritaan toos ah

⑦Ku qalabaysan 2D & 2.5D & 3D CAM nidaamka software-ka iskood u horumaray ee micromachining laser

Baaxadda codsiga:

Micromachining Laser ee qalabka qalliinka iyo lafaha sida endoscope adag & ultrasonic scalpel & endoscope& stapler & qalabka tolida & layliga jilicsan & planer & irbad dalool & sanka dalool

Mashiinka saxnaanta sare:

① Ballaca tolitaanka yar ee goynta: 18 ~ 30um

② Saxnaanta mashiinka sare: ≤ ± 10um

③Tayada wanaagsan ee jeexida: ma laha burr & jeexitaan siman

④ Waxtarka mashiinka sare: goynta hal-mar ah iyada oo loo marayo gidaarka hal dhinac ah & mashiin quudin joogto ah oo toos ah

Naqshad dabacsan

①Raac fikradda naqshadeynta ee ergonomics, jilicsan oo kooban

② Bixi shaqada ikhtiyaarka ah ee nidaamka aragtida mashiinka si aad waqtiga dhabta ah khadka tooska ah ula socoto habka farsamaynta firfircoonida laser

③Shaqooyinka software-ka iyo qalabku waxay u siman yihiin si dabacsanaan leh, waxay taageeraan qaabaynta shaqada shakhsi ahaaneed & maaraynta wax soo saarka caqliga leh

④ Taageer horumarinta naqshadeynta hal-abuurka laga bilaabo heerka qaybta ilaa heerka nidaamka

⑤ Xakamaynta nooca furan & nidaamka software micromachining laser waa sahlan tahay in lagu shaqeeyo & interface dareen leh

Wararka la xiriira

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur