Daawaynta dusha sare ee Laser waa tignoolajiyada adeegsata laydhka cufnaanta awooda sare leh si uu u kululeeyo dusha walxaha si aan xidhiidh lahayn, oo ogaanaysa wax ka beddelka dusha sare iyada oo la adeegsanayo qaboojinta korantada ee dusha walxaha lafteeda.Waa faa'iido leh in la hagaajiyo sifooyinka farsamada iyo jirka ee dusha maaddada, iyo sidoo kale caabbinta xirashada, caabbinta daxalka iyo caabbinta daalka ee qaybaha.Sanadihii la soo dhaafay, tignoolajiyada daaweynta dusha laser sida nadiifinta laysarka, deminta laser, alloying laser, xoojinta shoogga laysarka iyo annealing laser, iyo sidoo kale dhejinta laysarka, daabacaadda laser 3D, laysarka elektiroonigga ah iyo tignoolajiyada wax soo saarka kale ee laser-ka ayaa keenay rajooyin ballaadhan oo codsi ah. .

1. Nadiifinta leysarka

Nadiifinta Laser-ku waa tignoolajiyad cusub oo nadiifin ah oo si degdeg ah u koraysa, taas oo adeegsata laydhka garaaca wadnaha ee tamarta sare leh si ay u iftiimiso dusha sare ee qaybta shaqada, si wasakhda, qaybaha ama dahaarka dusha sare ay u baxaan ama u fidaan isla markiiba, sidaas darteed lagu gaadho habka nadiifinta iyo nadiifinta.Nadiifinta laser-ka waxaa inta badan loo qaybiyaa ka saarista miridhku, saarista saliidda, saarista rinjiga, saarista dahaarka iyo habab kale;Waxaa inta badan loo isticmaalaa nadiifinta biraha, nadiifinta haraaga dhaqameed, nadiifinta naqshadaha, iwm Iyada oo ku saleysan shaqooyinkeeda dhamaystiran, processing sax ah oo dabacsan, waxtarka sare iyo badbaadinta tamarta, ilaalinta deegaanka cagaaran, waxyeello lahayn substrate ah, sirdoonka, tayada nadiifinta wanaagsan. badbaadada, codsiga ballaaran iyo sifooyinka kale iyo faa'iidooyinka, waxay noqotay mid sii kordheysa oo caan ku ah beeraha kala duwan ee warshadaha.

Marka la barbar dhigo hababka nadiifinta dhaqameed sida nadiifinta jajabka farsamada, nadiifinta daxalka kiimikada, nadiifinta dareeraha adag ee nadiifinta, nadiifinta ultrasonic-soo noqnoqda, nadiifinta laysarka ayaa leh faa'iidooyin muuqda.

2. Deminta laser

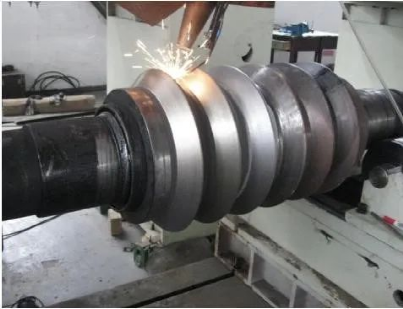

Deminta Laser-ku waxay isticmaashaa laysar tamar sare leh oo ah isha kulaylka si ay birta uga dhigto mid kulul oo qabow si degdeg ah.Habka deminta si degdeg ah ayaa loo dhammeeyaa si loo helo qallafsanaan sare iyo qaab dhismeedka martensite ultra-fine, hagaajinta qallafsanaanta oo xidho caabbinta dusha birta, iyo samaynta cadaadis cadaadis dusha sare si loo hagaajiyo caabbinta daalka.Faa'iidooyinka ugu muhiimsan ee habkan waxaa ka mid ah aagga kuleylka yar ee saameeya, qallafsanaan yar, heer sare oo otomaatig ah, dabacsanaan wanaagsan oo deminta xulashada, adkaanta sare ee badarka la safeeyey, iyo ilaalinta deegaanka ee caqliga leh.Tusaale ahaan, barta laysarka ayaa lagu hagaajin karaa si loo demiyo meel kasta oo ballac ah;Marka labaad, madaxa laysarka iyo isku xirka robot dhididka badan ayaa demin kara aagga loo qoondeeyay ee qaybaha adag.Tusaale kale, deminta laysarka waa mid aad u kulul oo degdeg ah, diiqada deminta iyo qallafsanaantuna waa yar yihiin.Qallafsanaanta shaqada ka hor iyo ka dib deminta laysarka ayaa la iska indho tiri karaa, sidaas darteed waxay si gaar ah ugu habboon tahay daaweynta dusha sare ee qaybaha leh shuruudaha saxda ah.

Waqtigan xaadirka ah, quenching laser ayaa si guul leh loogu dabaqay xoojinta dusha sare ee qaybaha nugul ee warshadaha baabuurta, warshadaha caaryada, qalabka qalabka iyo warshadaha mishiinada, gaar ahaan hagaajinta nolosha adeegga qaybaha nugul sida gears, sagxadaha usheeda dhexe, hagayaasha, daanka iyo caaryada.Astaamaha deminta laysarka waa sida soo socota:

(1) Deminta Laser-ku waa kuleyl degdeg ah iyo habka qaboojinta is-xakamaynta, kaas oo aan u baahnayn ilaalinta kulaylka foornada iyo deminta qaboojiyaha.Waa habraac kuleyl ah oo aan wasakhayn, cagaar iyo deegaan-saaxiibtinimo leh, waxayna si fudud u hirgelin kartaa deminta isku midka ah ee dusha sare ee caaryada waaweyn;

(2) Maaddaama xawaaraha kuleyliyaha laysarka uu yahay mid degdeg ah, aagga kulaylku saameeyaa waa yar yahay, iyo iskaanka dusha sare ee kuleylinta deminta, taas oo ah, daminta kuleylka maxalliga ah ee degdegga ah, qallafsanaanta dhimashada daweynta ayaa aad u yar;

(3) Iyadoo ay ugu wacan tahay xagasha kala duwanaanshaha yar ee laydhka laysarka, waxay leedahay toosan wanaagsan, waxayna si sax ah u demin kartaa dusha caaryada iyada oo loo marayo nidaamka hagaha iftiinka;

(4) Moolka lakabka adag ee deminta dusha laysarka guud ahaan waa 0.3-1.5 mm.

3. baabiinta leysarka

Xakamaynta Laser-ku waa habka daawaynta kulaylka oo adeegsata laysarka si uu u kululeeyo walxaha dusha sare leh, una soo bandhigta walxaha heerkul sare muddo dheer, ka dibna si tartiib ah u qaboojiya.Ujeedada ugu weyn ee habkani waa in la sii daayo walbahaarka, la kordhiyo ductility walxaha iyo adkaanta, iyo soo saarida qaab-dhismeed yar oo gaar ah.Waxaa lagu gartaa awoodda lagu hagaajinayo qaab-dhismeedka matrixka, la yareeyo adkaanta, nadiifinta miraha iyo baabi'inta walbahaarka gudaha.Sanadihii la soo dhaafay, technology annealing laser ayaa sidoo kale noqday geedi socodka cusub in warshadaha processing semiconductor, kaas oo si weyn u hagaajin kara isdhexgalka ee wareegyada isku dhafan.

4. Xoojinta shoogga laser

Tignoolajiyada xoojinta shoogga Laser waa tignoolajiyad cusub oo sare oo adeegsata mawjadda shoogga balaasmaha ee ay dhaliso laydhka xooggan ee laysarka si loo hagaajiyo daalka ka-hortagga, xidhashada caabbinta iyo iska caabbinta daxalka ee walxaha birta ah.Waxay leedahay faa'iidooyin badan oo muuqda, sida aagga kulaylka oo aan saameyn ku yeelan, hufnaanta tamarta sare, heerka cadaadiska aadka u sarreeya, xakameyn xooggan iyo saameyn xoojin cajiib ah.Isla mar ahaantaana, xoojinta shoogga laysarka waxay leedahay sifooyin cadaadis cadaadis cadaadis qotodheer oo qoto dheer, qaab-dhismeed yar oo wanaagsan iyo daacadnimada dusha sare, xasilloonida kulaylka oo wanaagsan iyo nolol dheer.Sanadihii ugu dambeeyay, tignoolajiyadani waxay gaartay horumar degdeg ah, waxayna door weyn ku leedahay hawada sare, difaaca qaranka iyo warshadaha militariga iyo qeybaha kale.Intaa waxaa dheer, daahan waxaa inta badan loo isticmaalaa si loo ilaaliyo workpiece ka gubanaya laser iyo kor u nuugista tamarta laser.Waqtigan xaadirka ah, alaabta daahan ee sida caadiga ah loo isticmaalo waa rinji madow iyo aluminium aluminium.

Laser peening (LP), oo sidoo kale loo yaqaan 'laser shock peening' (LSP), waa nidaam lagu dabaqo goobta injineernimada dusha sare, taas oo ah, adeegsiga alwaaxyada laysarka ee awoodda sare leh si loo abuuro culeysyo haraaga ah oo agabka ah si loo hagaajiyo caabbinta xirashada. (sida xidhashada caabbinta iyo iska caabinta daalka) ee dusha walxaha, ama si loo hagaajiyo xoogga qaybaha khafiifka ah ee alaabta si kor loogu qaado engeganaanta dusha sare ee alaabta.

Si ka duwan inta badan codsiyada wax ka qabashada walxaha, LSP uma isticmaasho awoodda laysarka ee daaweynta kulaylka si loo gaaro saameynta la rabo, laakiin waxay isticmaashaa saameynta iftiinka farsamada farsamaynta.Laydhka leysarka awoodda sare waxaa loo isticmaalaa in lagu saameeyo dusha sare ee shaqada bartilmaameedka leh garaaca garaaca gaaban ee tamarta sare.

Iftiinku wuxuu saameeyaa qaybta shaqada ee birta ah, wuxuu uumiga shaqada u soo saaraa xaalad balaasma dhuuban isla markaaba, wuxuuna ku dabaqaa cadaadiska hirarka shoogga qaybta shaqada.Mararka qaarkood lakabka khafiifka ah ee walxaha dhogorta leh ayaa lagu daraa shaqada shaqada si loo beddelo uumiga birta.Si loo cadaadiyo, alaabada kale ee daboolan ee daahsoon ama lakabyo faragelin la'aan ah ayaa loo isticmaalaa in lagu qabto balaasmaha (sida caadiga ah biyaha).

Plasma waxay soo saartaa saamaynta mawjada naxdinta leh, waxay dib u qaabaynaysaa qaab-dhismeed yar oo dusha sare ah ee qaybta shaqada ee barta saamaynta, ka dibna waxay abuurtaa falcelinta silsiladda ballaadhinta birta iyo isku-buufinta.Cadaadiska qoto dheer ee cadaadiska ka dhashay falcelintani waxay kordhin kartaa nolosha qaybta.

5. Laydhka leysarka

Laser alloying waa tignoolajiyada cusub ee wax ka beddelka dusha sare, kaas oo loo isticmaali karo in lagu diyaariyo amorphous nanocrystalline xoojisay daahan ka kooban cermet dusha sare ee qaybaha qaab-dhismeedka iyadoo loo eegayo shuruudaha adeegga kala duwan ee qalabka duulista iyo sifooyinka tamarta sare cufnaanta laydhka laydhka kululaynta iyo heerka uumiga, sidaas darteed. si loo gaaro ujeedada wax ka beddelka dusha sare ee alaabta duulista.Marka la barbar dhigo tignoolajiyada dahaadhka laysarka, tignoolajiyada dhejinta laysarka waxay leedahay sifooyin ka mid ah saamiga milanka yar yar ee substrate ilaa barkada dhalaalaysa, aagga kulaylka yar ee saameeya, qallafsanaanta kulaylka yar ee workpiece iyo heerka qashinka yar ee workpiece ka dib daawaynta laysarka.Xididada leysarka waxay si weyn u wanaajin kartaa sifooyinka dusha sare ee maaddooyinka, iyo hagaajinta alaabta la gashado.Waxay leedahay sifooyinka waxtarka sare leh, xawaaraha degdega ah, ilaalinta deegaanka cagaaran iyo wasakh-free, iyo waxqabadka wanaagsan ee workpiece ka dib daaweynta.

Tiknoolajiyada dhejinta leysarka sidoo kale waa mid ka mid ah tignoolajiyada cusub ee wax ka beddelka dusha sare ee matalaya jihada horumarinta iyo heerka injineernimada dusha sare.Tiknoolajiyada dhejinta laser-ka waxay noqotay goob cilmi baaris ah oo wax ka beddelka dusha sare ee Alloys titanium sababtoo ah faa'iidooyinka wasakhda-free iyo isku-dhafka birta ah ee u dhexeeya daahan iyo substrate-ka.Laydhka dahaarka dhoobada ah ama walxaha dhoobada ah ee la xoojiyay daahan isku dhafan ayaa ah hab wax ku ool ah oo lagu wanaajiyo iska caabbinta xirashada dusha sare ee daawaha titanium.Marka loo eego xaaladaha shaqada ee dhabta ah, dooro nidaamka walxaha ku habboon, iyo tignoolajiyada dhejinta laysarka waxay gaari kartaa shuruudaha habka ugu fiican.Tiknoolajiyada dhejinta laser-ka waxay hagaajin kartaa qaybo kala duwan oo guuldarraystay, sida dabaylaha aeroengine.

Farqiga u dhexeeya laysarka dusha sare ee laysarka iyo daboolka dusha sare ee laysarka ayaa ah in muraayadda dusha sare ee laysarka ay tahay in si buuxda loo isku daro walxaha alloy ee lagu daray iyo lakabka dusha sare ee substrate-ka ee xaalad dareere ah si loo sameeyo lakabka alloying;Laydhka dusha sare ee Laser-ku waa inuu dhalaa dhammaan waxyaalaha precoating-ka ah iyo micro dhalaalidda dusha sare ee substrate-ka, si lakabka daboolka ah iyo walxaha substrate-ka ah ay u sameeyaan isku-dhafka birta ah oo ay ku hayaan halabuurka lakabka daboolka aan isbeddelin.Laser alloying iyo teknoolajiyada dhejinta laysarka ayaa inta badan loo isticmaalaa si loo hagaajiyo caabbinta xidhashada dusha sare, caabbinta daxalka iyo caabbinta darajada ee Alloys titanium.

Waqtigan xaadirka ah, tignoolajiyada dhejinta laysarka ayaa si weyn loogu isticmaalay hagaajinta iyo hagaajinta meelaha birta ah.Si kastaba ha ahaatee, in kasta oo cladding laser-dhaqameed leeyahay faa'iidooyinka iyo sifooyinka processing dabacsan, dayactirka-qaabeeya gaar ah, wax lagu daro user-qeexay, iwm, hufnaantiisa shaqo waa hooseeyo, oo waxa ay weli ma buuxin karo shuruudaha wax soo saarka degdeg ah oo baaxad weyn iyo processing in beeraha wax soo saarka qaarkood.Si loo daboolo baahiyaha wax-soo-saarka tirada badan loona wanaajiyo hufnaanta xayndaabyada, tignoolajiyada-xawaaraha sare leh ee laysarka ayaa la sameeyay.

Tiknoolajiyada dhejinta laysarka ee xawaaraha sare leh waxay xaqiijin kartaa lakabka daboolka ee ciladaysan.Tayada dusha sare ee lakabka daboolku waa mid is haysta, isku xidhka birta ah ee substrate-ka, ma jiraan cillado furan, dushana waa siman yahay.Ma aha oo kaliya in lagu farsameyn karo jirka dib u soo celinta, laakiin sidoo kale diyaaradda iyo dusha adag.Iyada oo loo marayo hagaajin farsamo oo joogto ah, tignoolajiyadan waxaa si weyn loogu isticmaali karaa dhuxusha, birta, meelaha xeebaha, samaynta waraaqaha, qalabka madaniga ah, baabuurta, maraakiibta, batroolka, warshadaha hawada, oo noqda geeddi-socod dib-u-soo-saarid cagaaran ah oo bedeli kara tignoolajiyada elektiroonigga ah ee dhaqameed.

7. xaradhka Laser-ka

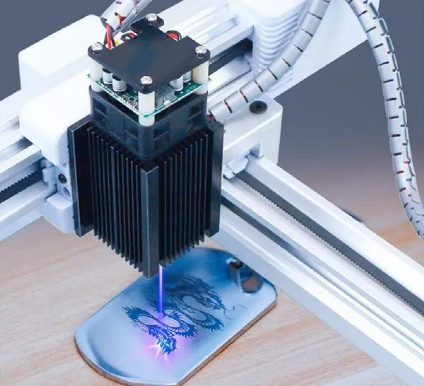

Xardhaynta Laser waa habka farsamaynta laysarka oo adeegsata tignoolajiyada CNC si ay u soo saarto laydhka tamarta sare leh ee dusha sare ee alaabta, waxaanay isticmaashaa saamaynta kulaylka ee ay dhaliso laysarka si ay u soo saarto habab cad oo dusha alaabta ah.Denaturation The jireed ee dhalaalidda iyo gasification ee alaabta processing hoos shucaac ah xardho laser awood kartaa xardho laser si loo gaaro ujeedooyin processing.xaradhka Laser waa in la isticmaalo laysarka si loo xardho erayada shay.Erayada ay xardhay tignoolajiyadani ma laha nicko, dusha shaygu waa siman yahay oo fidsan yahay, fartuna lama xidhi doono.Sifooyinkeeda iyo faa'iidooyinkeeda waxaa ka mid ah: badbaado iyo la isku halleyn karo;Si sax ah oo taxadar leh, saxnaanta waxay gaari kartaa 0.02mm;Badbaadinta ilaalinta deegaanka iyo agabka inta lagu jiro habaynta;Xawaaraha sare, xaradhka xawaaraha sare sida waafaqsan sawirada wax soo saarka;Qiimo jaban, oo aan ku xaddidnayn tirada farsamaynta, iwm.

8. Laser 3D daabacaadda

Nidaamku wuxuu qaadanayaa tignoolajiyada dhejinta laysarka, kaas oo isticmaala leysarka si uu u iftiimiyo socodka budada ee budada uu si toos ah u dhalaaliyo walaxda fudud ama budada daawaha.Ka dib marka laysarka laysarka uu baxo, dareeraha daawaha ayaa si degdeg ah u adkeysanaya si uu u garto prototying degdeg ah ee daawaha.Waqtigan xaadirka ah, waxaa si weyn loogu isticmaalay qaabaynta warshadaha, soosaarka mishiinnada, hawada sare, militariga, naqshadaha, filimada iyo telefishanka, qalabka guriga, warshadaha iftiinka, daawada, cilmiga qadiimiga, dhaqanka iyo farshaxanka, farshaxanimada, dahabka iyo qaybaha kale.

9. Codsiyada warshadaha caadiga ah ee daaweynta dusha laser iyo dib-u-soo-saarka

Waqtigan xaadirka ah, daaweynta dusha laser-ka iyo teknoolojiyadda wax-soo-saarka wax-soo-saarka, hababka iyo qalabka ayaa si ballaaran loogu isticmaalaa birta, mashiinnada macdanta, caaryada, awoodda batroolka, qalabka qalabka, gaadiidka tareenka, hawada hawada, mashiinnada iyo warshadaha kale.

10. Codsiga tignoolajiyada elektiroonigga laysarka

Electroplating Laser waa tignoolajiyada cusub ee tamarta sare ee tamarta tamarta, taas oo muhiimad weyn u leh wax soo saarka iyo hagaajinta aaladaha microelectronic iyo wareegyada isku dhafan ee baaxadda weyn.Waqtigan xaadirka ah, in kasta oo mabda'a electroplating laser, ablation laser, dhigista laser plasma iyo jet laser weli cilmi baaris ayaa lagu hayaa, tignoolajiyadooda ayaa la adeegsaday.Marka laser joogto ah ama laser garaaca garaaca dusha cathode ee qubeyska elektiroonigga ah, ma aha oo kaliya in heerka dhigista birta si weyn loo wanaajin karo, laakiin sidoo kale kumbuyuutarka ayaa loo isticmaali karaa in lagu xakameeyo jihada iftiinka laysarka si loo helo dahaarka aan la daboolin ee joomatari adag oo la filayo.

Codsiga laysarka elektiroonigga ah ee ficil ahaan wuxuu inta badan ku saleysan yahay labada astaamood ee soo socda:

(1) Xawaaraha aagga shucaaca laysarka ayaa aad uga sarreeya xawaaraha korantada ee jirka (qiyaastii 103 jeer);

(2) Awoodda xakamaynta laysarka waa mid xooggan, taas oo ka dhigi karta qaybta lagama maarmaanka ah ee maaddadu inay soo dedejiso qaddarka loo baahan yahay ee birta ah.Koronto-samaynta caadiga ah waxay ku dhacdaa dhammaan qalabka korantada, iyo xawaaraha korantada waa mid gaabis ah, markaa way adagtahay in la sameeyo qaabab adag oo fiican.Electroplating Laser-ku wuxuu hagaajin karaa iftiinka laysarka ilaa cabbirka mikrometerka, wuxuuna samayn karaa baafin aan gaashaanka lahayn oo cabbirkiisu yahay mikrometerka.Naqshadeynta wareegga, dayactirka wareegga iyo dejinta degaanka ee qaybaha isku xirka microelectronic, nooca khariidaynta xawaaraha sare ayaa noqonaysa mid aad iyo aad u badan.

Marka la barbar dhigo electroplating caadiga ah, faa'iidooyinkeedu waa:

(1) Xawaaraha dhigista degdega ah, sida dahaadhka dahabka leysarka ilaa 1 μM/s, dhejinta naxaasta leysarka ilaa 10 μ M/s μ m/s;

(2) Dhigista birta waxay ku dhacdaa oo keliya aagga shucaaca laysarka, iyo dahaarka dhigaalka maxalliga ah ayaa la heli karaa iyada oo aan la qaadin tallaabooyin ilaalin ah, sidaas darteed fududeynaya habka wax soo saarka;

(3) Xabagta daahan ayaa si weyn loo hagaajiyay;

(4) Si fudud loo xaqiijiyo xakamaynta tooska ah;

(5) Keydi biraha qaaliga ah;

(6) Badbaadinta maalgashiga qalabka iyo wakhtiga habaynta.

Marka leysarka joogtada ah ama laser-ku-jiidhiyuhu uu iftiimiyo dusha sare ee cathode ee qubeyska elektiroonigga ah, ma aha oo kaliya in heerka dhigista birta si weyn loo wanaajin karo, laakiin sidoo kale kombuyuutarku wuxuu xakameyn karaa dhaqdhaqaaqa dhaqdhaqaaqa laysarka si uu u helo dahaarka aan la daboolin ee leh dhismaha la filayo. joomatari.Tiknoolajiyada cusub ee hadda jirta ee jet-ka laser-ka ee la xoojiyey waxay isku daraysaa tignoolajiyada kor loo qaaday ee laser-ka iyo buufinta xalka elektiroonigga ah, si laser-ka iyo xalka dahaadhka ay isku mar u toogtaan dusha sare ee cathode, xawaaraha wareejinta mass aad ayuu uga dhakhso badan yahay xawaaraha wareejinta tirada badan. kicinta yar yar ee ay keento shucaaca laysarka, taas oo lagu gaadhayo xawli aad u sarreeya.

Horumarka mustaqbalka iyo hal-abuurka

Mustaqbalka, jihada horumarinta ee daaweynta dusha laysarka iyo qalabka wax soo saarka dheeraadka ah waxaa lagu soo koobi karaa sida soo socota:

Waxtarka sare - wax ku oolnimada sare ee wax-ku-oolnimada, buuxinta laxanka wax-soo-saarka degdegga ah ee warshadaha casriga ah;

· Waxqabadka sare - qalabku wuxuu leeyahay shaqooyin kala duwan, waxqabad xasiloon wuxuuna ku habboon yahay xaaladaha shaqada ee kala duwan;

Sirdoonka sare - heerka garaadka ayaa si joogto ah u soo hagaagaya, iyada oo faragelin yar oo gacanta ah;

Qiimaha jaban - Qiimaha qalabku waa la xakameyn karaa, waxaana la dhimay qiimaha alaabta la isticmaalo;

Habaynta - qalabaynta gaarka ah ee qalabka, adeegga iibka ka dib ee saxda ah,

Iyo isku-darka - isku-darka tignoolajiyada laysarka iyo tignoolajiyada habaynta dhaqanka.

Waqtiga post: Seb-17-2022