Xalka saxda ah 3c

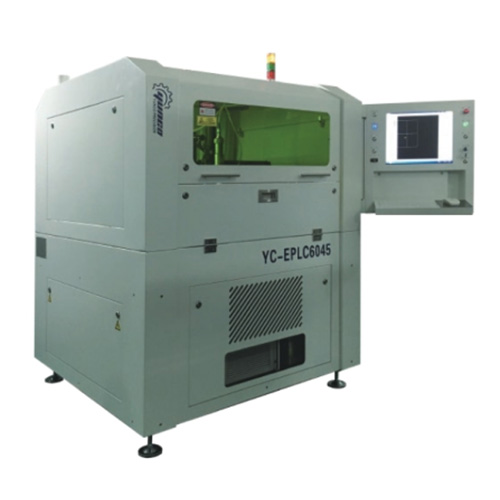

EPLC6045 Mashiinka Goynta Laser ee Qalabka Birta Ah ee Saxda ah

Mashiinka goynta laser qalab bir ah oo sax ah

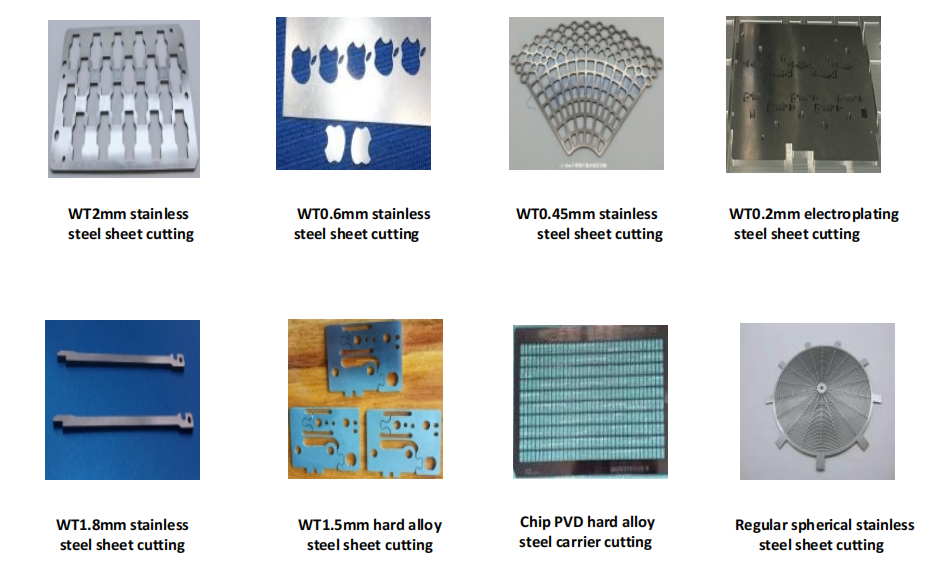

Mashiinka goynta laser qalab bir ah oo sax ahwaa nooc ka mid ah micromachining laser si gaar ah loo isticmaalo goynta, qodista iyo goynta birta aan lahayn, birta daawaha adag iyo agabka kale ka hor iyo ka dib daaweynta dusha.Sida jarista iyo samaynta xaashida birta, goynta iyo samaynta xaashida birta daawaha, goynta iyo samaynta chip PVD birta adag ee adag, goynta iyo samaynta xaashida birta ah ee caadiga ah, goynta iyo samaynta xaashida birta birta ah ka dib PVD, goynta iyo samaynta xaashida birta silikoon, goynta iyo samaynta qaybaha qaab dhismeedka taleefanka gacanta, iwm. Qalabka saxda ah ee birta aan lahayn mashiinka goynta laser ayaa ka gudbay shahaado 3C wuxuuna leeyahay faa'iidooyinka naqshad horumarsan, hawlgal fudud iyo saxnaanta farsamaynta sare.

Qiyaasta Farsamada

| Xawaaraha ugu badan ee hawlgalka | 1000mm/s(X);1000mm/s(Yl&Y2);50mm/s(Z); |

| Meelaynta saxnaanta | ±3um (X) ±3um (Y1&Y2) ;±5um (Z) ; |

| Saxnaanta meelaynta soo noqnoqda | ±1um(X) ;±1um (Y1&Y2) ;±3um(Z); |

| Qalabka mashiinka | Saxnaanta birta aan fiicnayn iyo birta daawaha adag ka hor ama ka dib daaweynta dusha; |

| Dhumucda darbiga maadada | 0 ~ 2.0 ± 0.02 mm; |

| Kala duwanaanshaha mashiinka diyaaradda | 450mm*600mm; |

| Nooca laser | Fiber laser; |

| Dhererka hirarka leysarka | 1030-1070±10nm; |

| awoodda laysarka | CW200W&250W&300W&500W&1000W&QCW150W ikhtiyaarka ah |

| Qalabka korontada | 220V ± 10%, 50Hz;AC 20A (goobiyaha ugu weyn); |

| Qaabka faylka | DXF, DWG; |

| Cabirka | 1280mm*1320*1600mm; |

| Miisaanka qalabka | 1500kg; |

Tusaalaha Bandhiga

Baaxadda codsiga

Micromachining Laser ee diyaaradda iyo qalabyada sagxadaha qaloocan ee birta aan fiicnayn iyo daawaynta birta adag

Mashiinka saxnaanta sare

1.Small goynta tolida ballac: 15 ~ 30um

2. Saxnaanta mashiinka sare: ≤ ± 10um

3.Tayada wanaagsan ee jeexitaan: jeexitaan siman & aagga kulaylka yar ee saameeya & burka yar

4.Size refinement: cabbirka badeecada ugu yar waa 20um

La qabsi xoog leh

1.Have awooda goynta laysarka, qodista, godad, calaamadaynta iyo xirfadaha kale ee processing wanaagsan ee diyaaradda & qalabka dusha qalooca

2.Can mashiinka laser micromachining diyaaradda iyo sagxadaha qaloocan

3. Qalabaysan is-horumarin toos ah wadista moobilka labajibbaaran ee dhaqdhaqaaqa saxda ah ee dhaqdhaqaaqa, madal granite, aluminium aluminium granite beam doorashada

4. Bixinta shaqada ikhtiyaariga ah, sida labajibbaaran xarun & Meelaynta muuqaalka & quudinta tooska ah iyo nidaamka dejinta & kormeer firfircoon iwm.

5. Qalabaysan is-horumarin dheer & dherer gaaban oo is-horumariyay, biibiile fiiqan & biibiile siman madaxa goynta laser-ka fiican

6.Ku qalabaysan qaadashada walxaha modular iyo nidaamka dhuumaha boodhka ka saarida

7.Sii is-horumariyay jir kacsanaan dhaqaaqi karo & jir kacsanaan go'an & xayeysiis faaruq ah & saxan malabka, iwm. qalab ikhtiyaari ah

8.Ku rakibay nidaamka software-ka 2D & 2.5D & 3D CAM ee iskood u horumaray ee micromachining laser

Naqshad dabacsan

1.Raac fikradda naqshadeynta ee ergonomics, jilicsan oo kooban

2.Flexible software & hardware collocation function , taageeraya qaabeynta shaqada shakhsi ahaaneed & maaraynta wax soo saarka caqliga leh

3.Support togan design innovation from level unit to level system

4.Open control & nidaamka software micromachining laser fudud in ay ku shaqeeyaan & interface dareen leh

Shahaadada farsamada

CE

ISO9001

IATF16949

Wararka la xiriira

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur